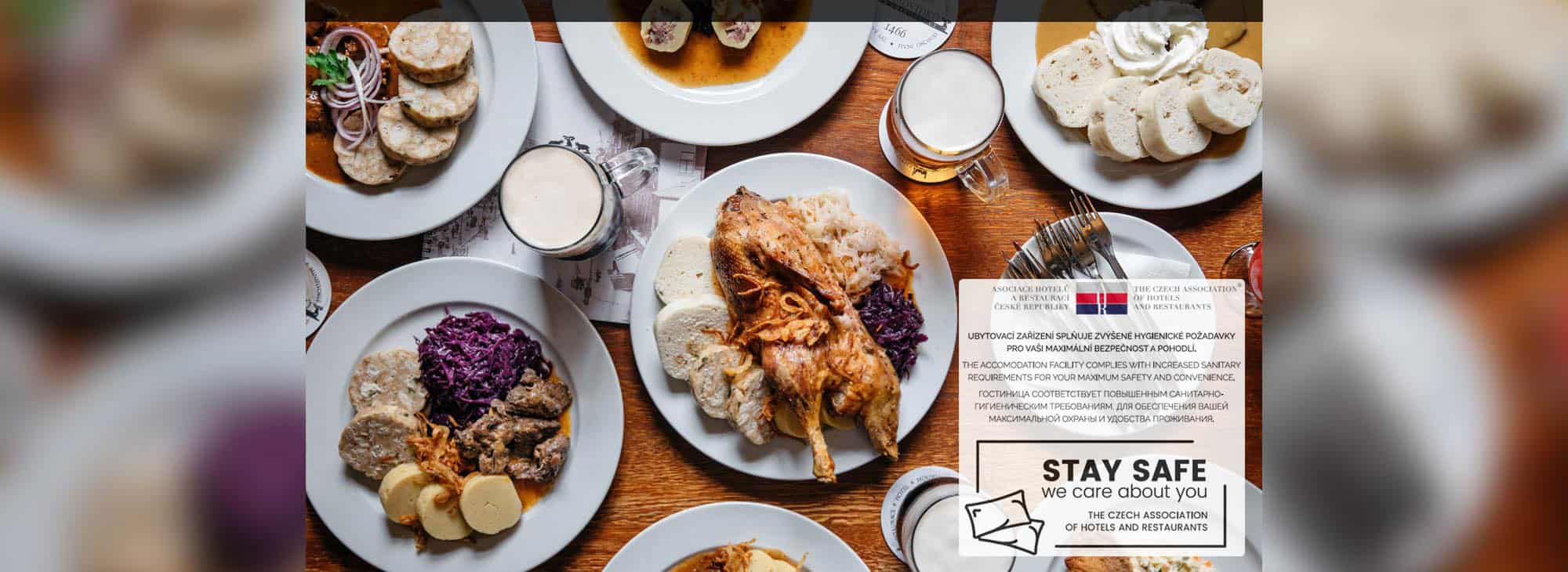

The history of the restaurant ” U medvídků” dates back to 1466. In the past century the original brewery was converted into the first Prague cabaret and also into the one of the biggest beerhall in Prague.

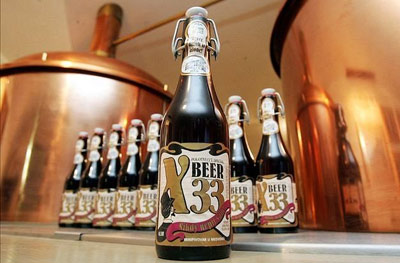

The mini-brewery is biggest attraction for our guests. It makes the STRONGEST BEER in the world, XBEER-33, using historical technology.

During the reconstruction of the restaurant a hotel*** was built in the historical premises with 45 rooms. (including hygienic facilities, SAT, TV, safe and telephone).

HOTEL - 00420 224 211 916 |

HOTEL - 00420 224 211 916 |

Hotel, restaurace a pivovar U Medvídků

Hotel, restaurace a pivovar U Medvídků 00420 224 220 930

00420 224 220 930 WIFI FREE |

WIFI FREE |